What?

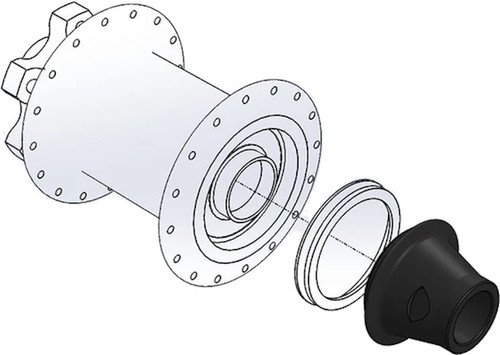

Boostinator kits allow non-boost wheels to be mounted in Boost spacing frames and forks. Boostinator kits consist of a specially-designed axle end cap and, in the case of rear kits, a precision-machined rotor spacer with a set of six high-strength bolts. In keeping with Boost specifications, the disc and cassette are shifted outboard, allowing brakes and derailleurs to function as designed.

Why?

The benefits of the "Boost" 15x110mm front and 12x148mm rear axle standards are clear: better clearance for fatter tyres & rims and reduced dish for stiffer, stronger wheels. The big bummer? Taking full advantage requires not only a new frame and fork, but new wheels as well. Boostinator kits allow non-boost wheels to be mounted in Boost spacing frames and forks.

How?

In response, Wolftooth have developed the Boostinator. When paired with compatible 15x100mm or 12x142mm hubs, Boostinator kits allow existing wheels to be mounted in Boost-standard frames and forks. Disc and drivetrain positions are maintained and, thanks to a quick re-dish, spoke bracing angles are improved.

*Note: Re-Dishing of the rear wheel will be required*

Boostinator DF2 Compatibility

The new 2017 DT Swiss 1500 series front wheels are not compatible with the DF2 (front boostinator). To determine if your wheelset is compatible, remove the non-rotor side endcap and measure the OD. If the OD is 28mm, the DF2 is NOT compatible. The DF2 is only compatible if the OD is ~29.7mm.

The Boostinator DF2 is also compatible with some complete DT Swiss Spline One front wheels.

. Front XR 1501 Spline One (2016 and older) DF2

. Front EX 1501 Spline One (2016 and older) DF2

. Front EX 1501 Spline One (2016 and older) DF2

Boostinator DF2 Installation

Tools and Supplies Required:

. Protective eyewear

. Torque wrench with T25 bit

. Pliers

. Clean rag

Recommended:

. Truing stand

. Spoke wrench

. 2x1in section of old inner tube

Mounting Instructions:

. Use pliers to pull drive-side end cap from hub

. Use old inner tube to protect end cap finish from pliers

. Pull firmly along hub axis: end cap is held in place with internal o-ring

. Use rag to clean end cap recess and exposed hub axle

. Press Boostinator end cap into hub axle

. Press firmly until met with a hard (metal-on-metal) stop. O-ring will hold end cap in place

Re-Dishing Wheel:

*Important: If unfamiliar with wheel building or truing, we strongly recommend taking your Boostinated wheel to a local shop for re-dishing.*

. Mount wheel in truing stand

. True wheel to remove any major hops or wobbles

. Re-dish wheel by loosening disc side and tightening drive-side spokes 1/4-turn per pass

. If previously true and properly dished, most wheels will require less than 1/2-turn tightening on drive-side spokes and less than one turn loosened from the disc-side spokes

. De-tension and true wheel as needed

Boostinator kits allow non-boost wheels to be mounted in Boost spacing frames and forks. Boostinator kits consist of a specially-designed axle end cap and, in the case of rear kits, a precision-machined rotor spacer with a set of six high-strength bolts. In keeping with Boost specifications, the disc and cassette are shifted outboard, allowing brakes and derailleurs to function as designed.

Why?

The benefits of the "Boost" 15x110mm front and 12x148mm rear axle standards are clear: better clearance for fatter tyres & rims and reduced dish for stiffer, stronger wheels. The big bummer? Taking full advantage requires not only a new frame and fork, but new wheels as well. Boostinator kits allow non-boost wheels to be mounted in Boost spacing frames and forks.

How?

In response, Wolftooth have developed the Boostinator. When paired with compatible 15x100mm or 12x142mm hubs, Boostinator kits allow existing wheels to be mounted in Boost-standard frames and forks. Disc and drivetrain positions are maintained and, thanks to a quick re-dish, spoke bracing angles are improved.

*Note: Re-Dishing of the rear wheel will be required*

Boostinator DF2 Compatibility

The new 2017 DT Swiss 1500 series front wheels are not compatible with the DF2 (front boostinator). To determine if your wheelset is compatible, remove the non-rotor side endcap and measure the OD. If the OD is 28mm, the DF2 is NOT compatible. The DF2 is only compatible if the OD is ~29.7mm.

The Boostinator DF2 is also compatible with some complete DT Swiss Spline One front wheels.

. Front XR 1501 Spline One (2016 and older) DF2

. Front EX 1501 Spline One (2016 and older) DF2

. Front EX 1501 Spline One (2016 and older) DF2

Boostinator DF2 Installation

Tools and Supplies Required:

. Protective eyewear

. Torque wrench with T25 bit

. Pliers

. Clean rag

Recommended:

. Truing stand

. Spoke wrench

. 2x1in section of old inner tube

Mounting Instructions:

. Use pliers to pull drive-side end cap from hub

. Use old inner tube to protect end cap finish from pliers

. Pull firmly along hub axis: end cap is held in place with internal o-ring

. Use rag to clean end cap recess and exposed hub axle

. Press Boostinator end cap into hub axle

. Press firmly until met with a hard (metal-on-metal) stop. O-ring will hold end cap in place

Re-Dishing Wheel:

*Important: If unfamiliar with wheel building or truing, we strongly recommend taking your Boostinated wheel to a local shop for re-dishing.*

. Mount wheel in truing stand

. True wheel to remove any major hops or wobbles

. Re-dish wheel by loosening disc side and tightening drive-side spokes 1/4-turn per pass

. If previously true and properly dished, most wheels will require less than 1/2-turn tightening on drive-side spokes and less than one turn loosened from the disc-side spokes

. De-tension and true wheel as needed

. Convert your non-boost wheels to fit boost frames

. The Boostinator DF2 is compatible with DT-Swiss 2011 and newer 15x100mm 240s front hubs

. Use DF-20 for 240s Oversize (20mm convertible) hubs

. These hubs have a threaded non-disc side endcap that has little wrench flats on it

. Centerlock hubs are supported

Technical Specifications

. Material: 6061 aluminium

. Included: Rear kits come with appropriate-length Class 10.9 bolts - each roughly 40% stronger than more common Class 8.8 hardware

. Net weight: 6g